Primilis Ltd © 2018 All Rights Reserved

Working with you to build a better business

We have experience in developing tools to provide MRP functionality that wasn’t available in existing systems and enable the planning of purchasing and manufacturing and the minimisation of stock and cost.

A manufacturer of high performance and complex electronic systems had installed a Sage accounting system.

The system managed stock but had no manufacturing management or material planning capability, both of which were needed by the company as it expended its manufacturing operations.

Tom Gaskell‡ was asked to put in manufacturing control, make it work in the company’s in-house manufacturing facility, and extend the system to provide Material Requirements Planning (MRP) capability.

Working closely with the company’s Finance and Operations staff he integrated a manufacturing control add-on into the Sage system, configured it, then trained the staff in its use.

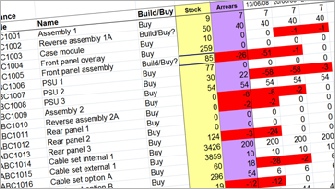

To provide the material planning facility he designed, implemented and trained staff in the use of a suite of 18 different tools that comprehensively reported on materials and manufacturing status and identified purchasing requirements.

These tools provided MRP functionality that wasn’t available in either the company’s basic Sage system or its manufacturing add-on.

They enabled the company to accurately plan and expedite purchasing and manufacturing whilst minimising stockholding, reducing waste and cutting costs.

ask us how you can improve your material and manufacturing management systems »

‡ Director, Primilis

Material planning system

“The tools that Tom put in gave us all the things that were missing in our original system; we had been struggling before they arrived. We were very impressed with how quickly the tools were developed and with their flexibility. They were the critical elements that enabled us to keep cost under control and manage our stock.”

Jonathan Wells

VP Operations

| Why Primilis? |

| Our approach |

| Cost, risk, effectiveness |

| Business processes |

| Product quality |

| Manufacturing |

| Trouble-shooting |

| Quality Management - ISO 9001 |

| Material planning |

| Improving reliability |

| Reducing defects |

| Assembly and test centre |

| In-house manufacturing |

| Changing manufacturer |

| CE marking |

| Trouble-shooting |

| Sitemap |

| Search |